Abrasive belt slitting machine

Abrasive cloth slitting machine

This machine is equipped with well-known brand frequency conversion motor, through the advanced control system set, the product dynamic performance is good, high precision, response is fast, high stability, to achieve higher production efficiency, is the industry's preferred abrasive cloth slab-type.

Abrasive cloth slitting machine system includes

Professional CNC system for slitting abrasive cloth (intelligent rectifying machine configuration, common models do not have this configuration) :

L precision drive system

Precision pneumatic control system

Automatic feeding auxiliary system: feeding system, air pump, air pipe, etc

1 year warranty (except consumables, consumables include cutting knives, sealing rings, etc.)

Technical parameters:

Product name: abrasive cloth slitter

Main machine appearance size (mm) : 2200*2200*1200

Voltage: 380V 50HZ

Machine power: 3.5kw

Weight: 1000 kg

Cutting speed: 4-8 min/m

Applicable to emery cloth width: 1460MM

Applicable feeding length: 50-120

Applicable width of strip: 14mm-22mm

Motion control system: imported inverter + brand reducer + variable frequency motor

Feeding system: yade polite cylinder

Core configuration features:

1. Internationally advanced construction machinery structure mechanical design, selected high-quality alloy materials, by the professional CNC machining center overall fine milling fine grinding processing, one molding, stable and durable.

2. High-strength welding body, tempering aging treatment, five-face milling, drilling and tapping, to ensure the rigidity and accuracy of the equipment, stable and non-deformation.

3. Pneumatic device adopts high precision transmission mechanism, equipped with advanced international standard installation mode, quick and accurate response, good wear resistance.

4. Professional brand electrical components and industrial control system with perfect functions and stable performance.

Equipment operation characteristics:

1. USES scissors cutting technology, precision mechanical action structure, uniform cutting and smooth, easy to learn.

2. imported frequency converter, brand frequency conversion motor, feeding adopts pneumatic automatic feeding, loading and unloading is convenient.

3. winding adopts straight push wheel, to ensure that the winding is flat and level.

4. high material utilization, emery cloth length and width adjustable precision, simple operation and fast.

5. spindle and circular knife use CVT system, can work in high and low adjusting speed and positive &negative switching control.

6. puller package rubber roller made of imported rubber surface with precision cylindrical grinding machine processing, deformation, discharge is flat and level.

7. guide roller part, using chrome-plated steel tube, each treated with dynamic balance.

Main functions:

The emery cloth slitter adopts the new design concept, and carries out the integration and optimization of each part based on the previous generation of products, making the whole machine structure more precise and stable, and effectively improving the stability and durability of products.Sand cloth slitting machine is suitable for 1.5m wide, 50-120m long various brands of sand cloth volume slitting, strip width can be customized according to customer requirements.

Aluminium Oxide Flap Disc

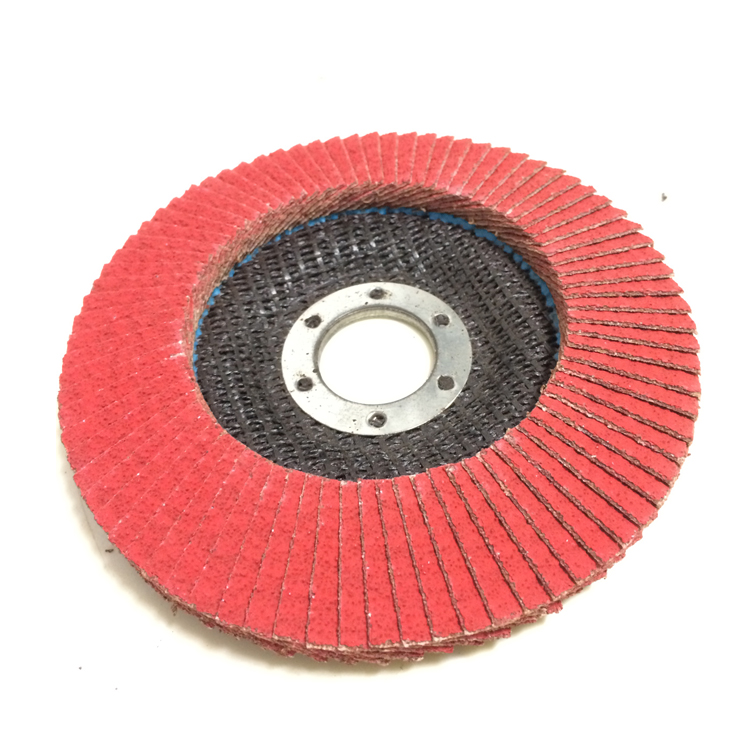

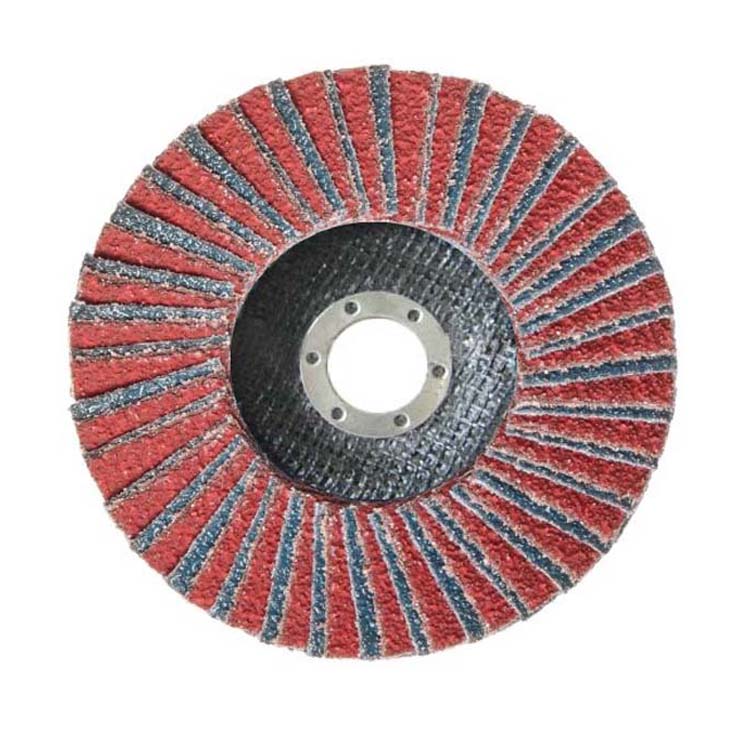

Ceramic Grain Flap Disc

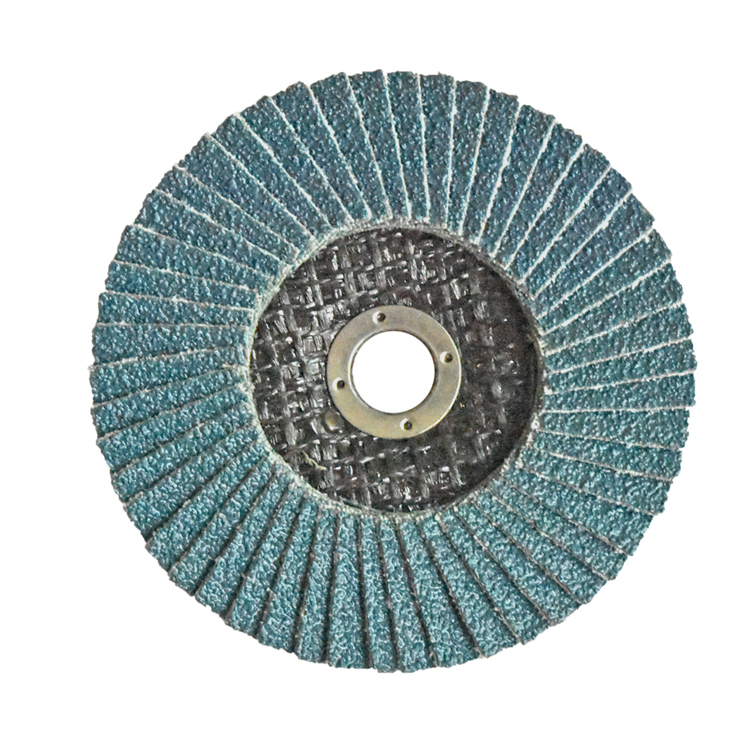

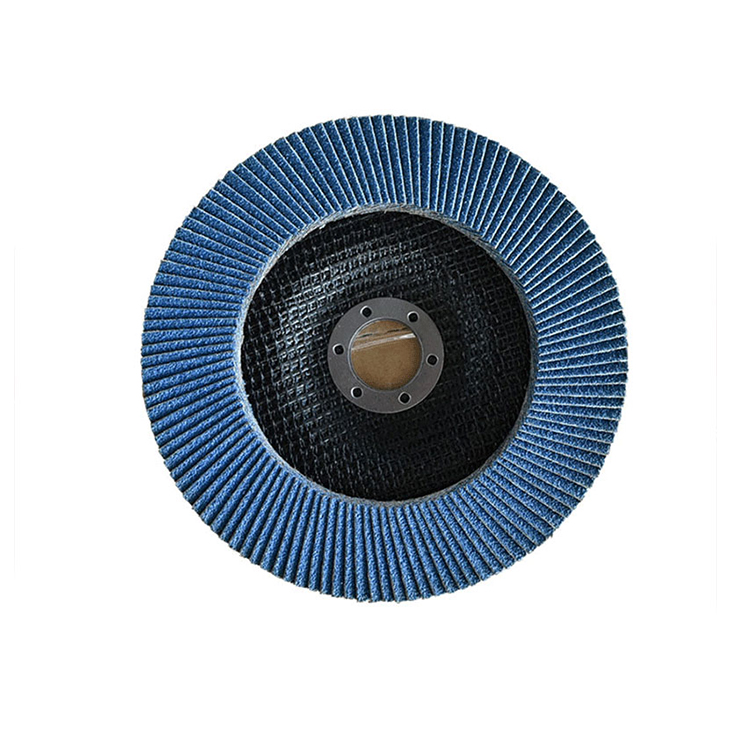

Zirconia Alumina Flap Disc

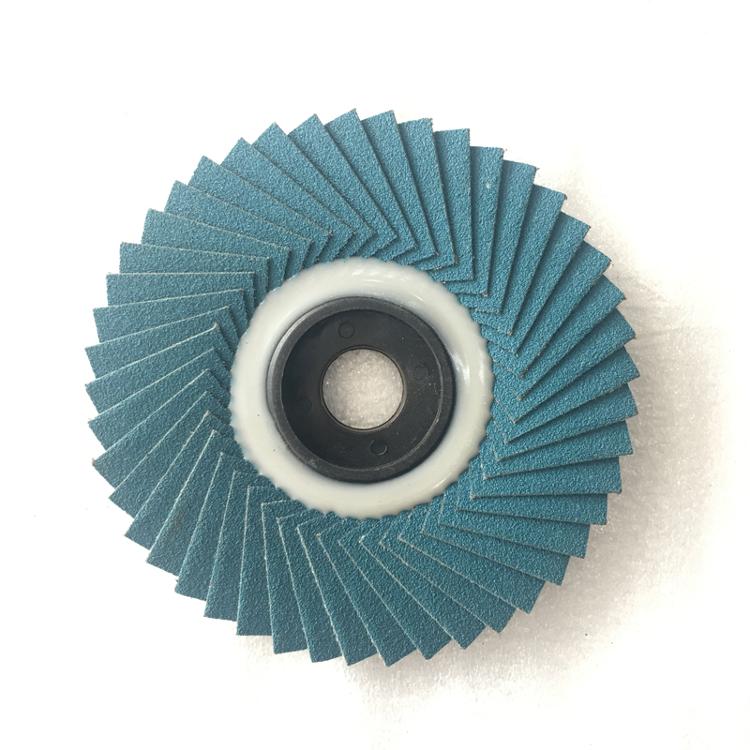

Radial Flap Disc

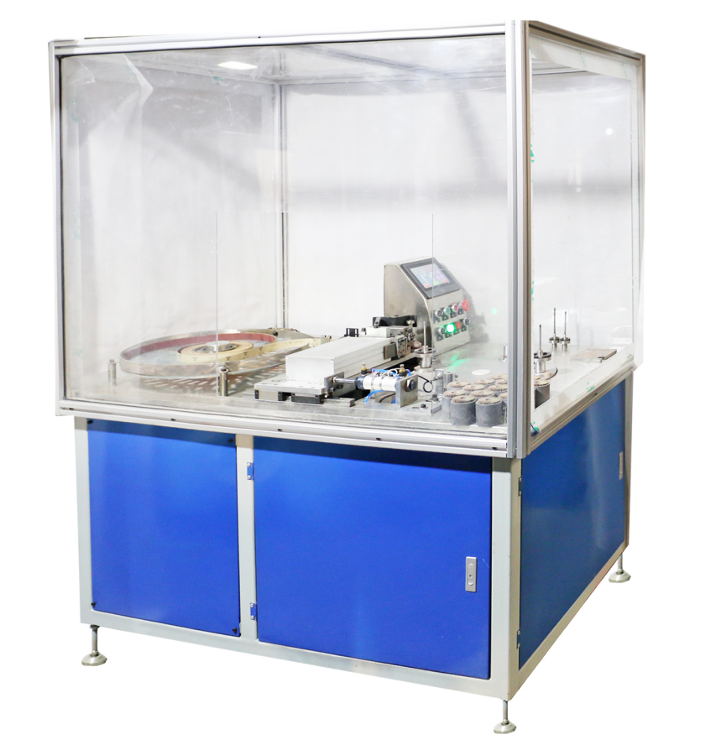

Fully automatic labeling machine

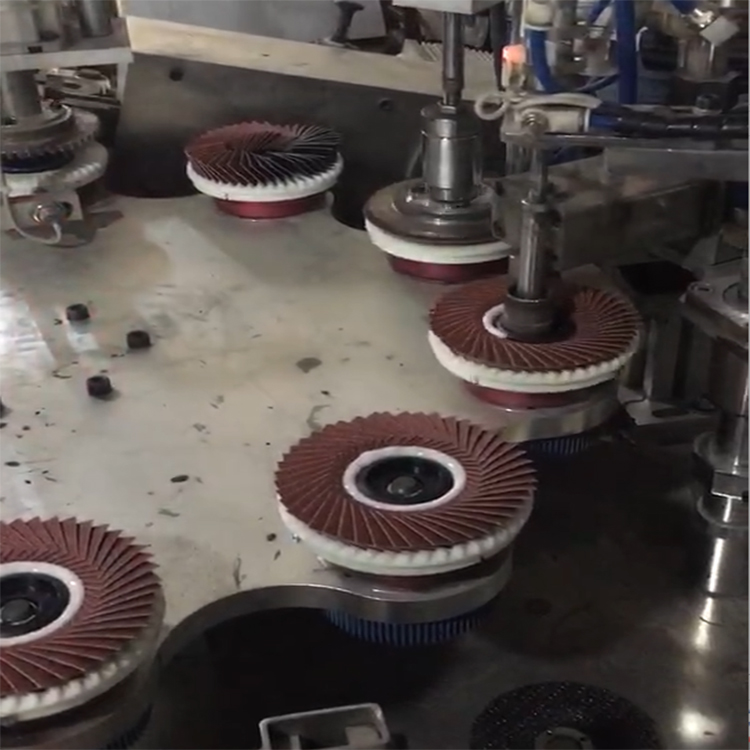

Semi-automatic flap disc machine

Abrasive belt slitting machine

Semi-automatic mounted flap wheel machine

Flexible Flap Disc Machine

Abrasive cloth roll slitter machine

Full automatic flap disc machine

Narrow Abrasive Belt Slitting Machine

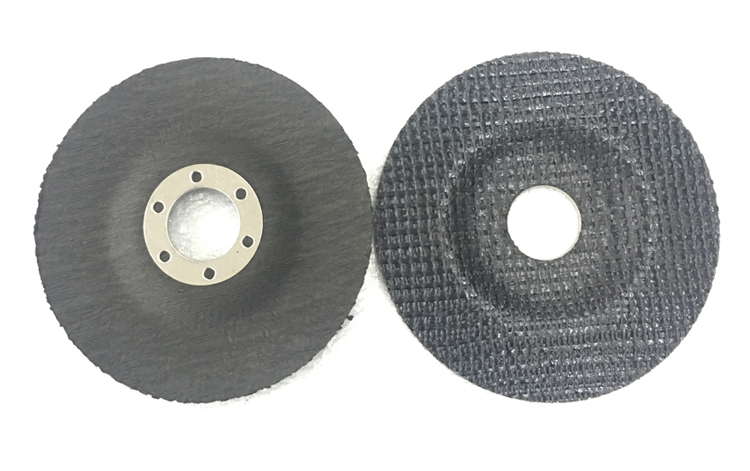

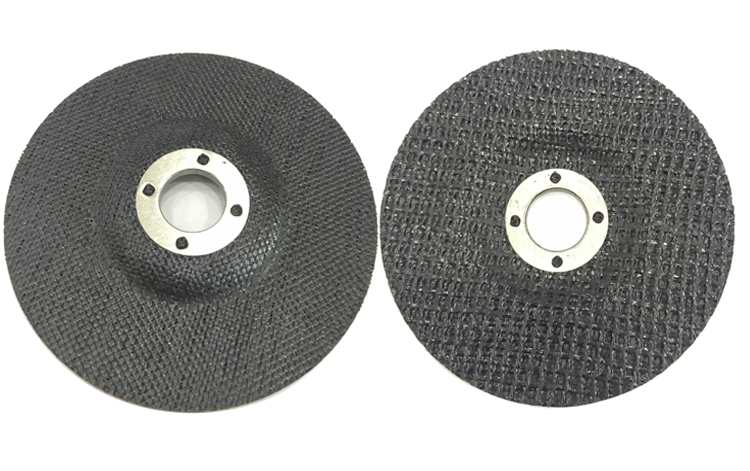

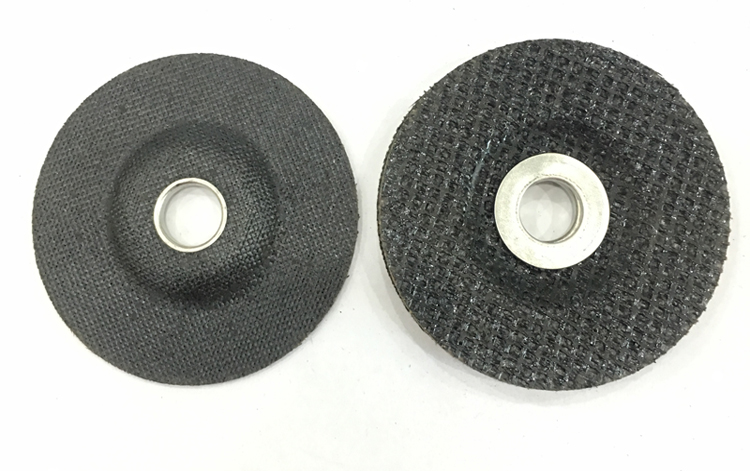

One Metal Ring Fiberglass Backing Pad Without Pressing

Non-woven Abrasive Belt

Non-woven polishing wheel

Compact Abrasive Belt

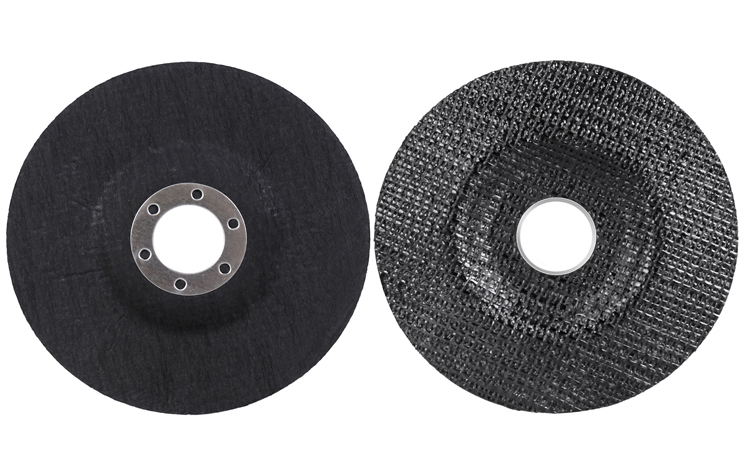

Glass Fiber Backing Plate with OEM Label

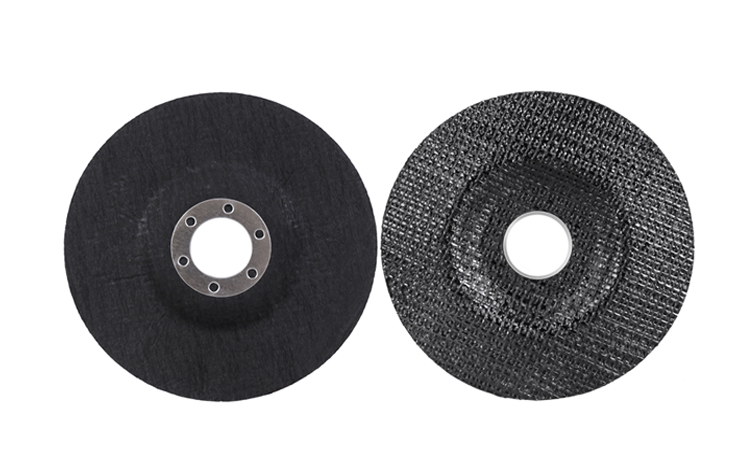

Fiberglass Backing Pad with Woven Cloth Surface

Glass Fiber Backing Pads with Non-woven Fabric Surface

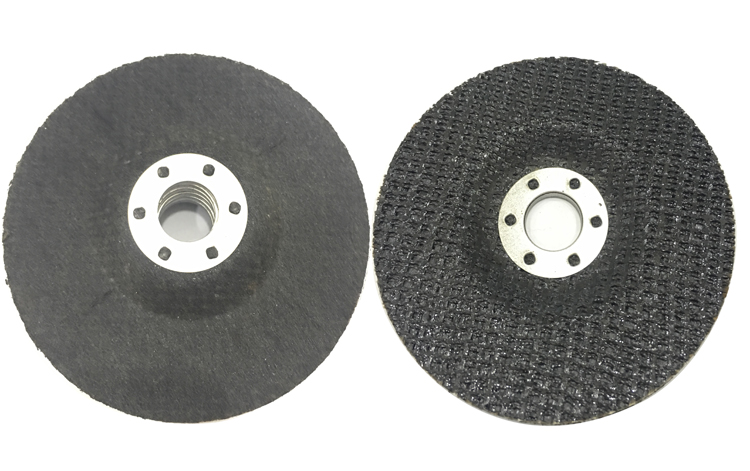

Fiberglass Backing Plate with Black Paper Surface

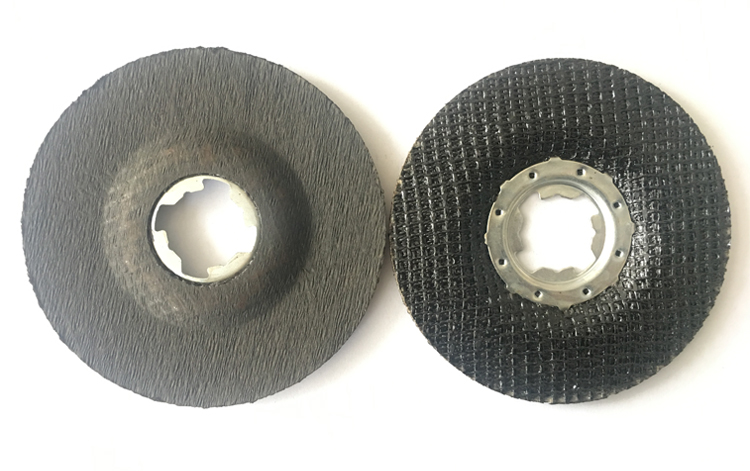

Fiberglass Backing Plate with Higher Metal Ring

X-lock Fiberglass Backing Pad

One Metal Ring Fiberglass Backing Plate with Pressing

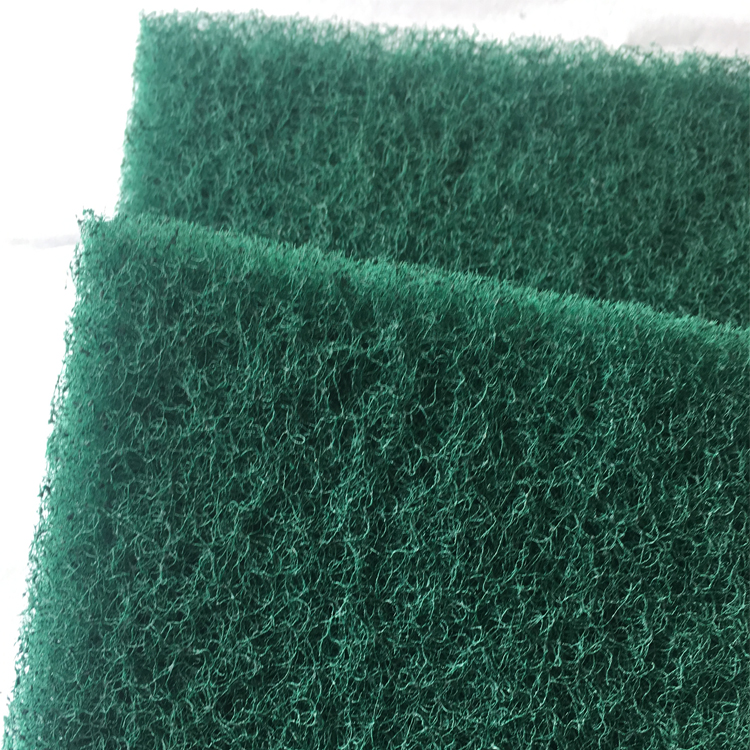

Scouring pad

Abrasive cloth roll

Abrasive sheet

Flexible Grinding Wheel

Elastic grinding wheel

Fiber Discs

Hook and loop disc

Strip and Clean Disc

Combined Flap Discs

Diamond Flap Disc

Vertial Flap Discs

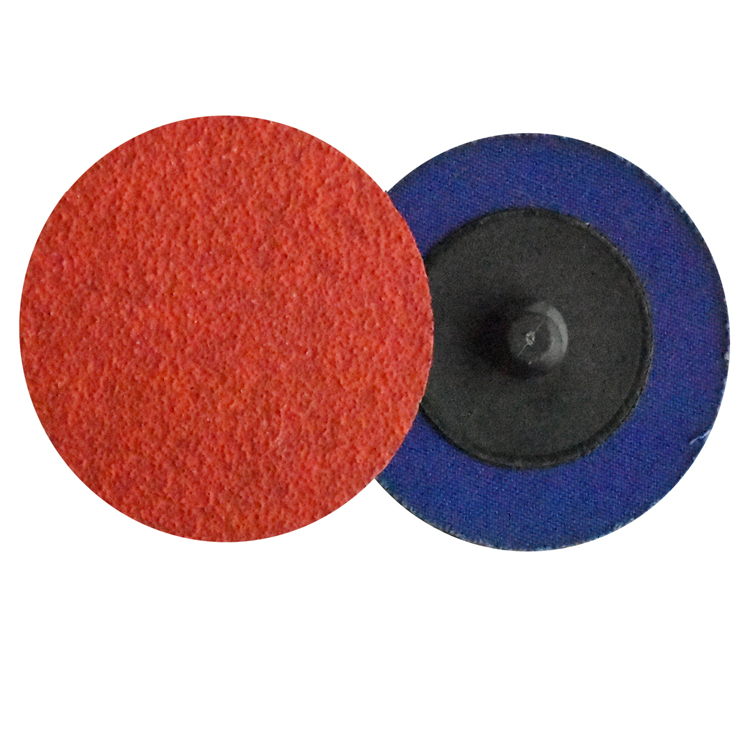

Quick Change Disc

Felt Disc

Non-woven Flap Discs

Alumina Oxide Abrasive belt

Zirconia Alumina Abrasive Belt

Silicon Carbide Abrasive Belt

Ceramic Grain Abrasive Belt

Flap Wheel with Shank

Flap Wheel with Calcined AO

High Destiny Flap Wheel

Abrasive Wire Flap Wheel

Flap Wheel with Silicon Carbide

Customized Special Shape Flap Wheel

Flap Wheel with Aluminium Oxide

Flap wheel with Zirconia Alumina

Deefors Zirconia Alumina Flap Disc

Depressed Center Grinding Wheel

Depressed Center Cutting Disc

Supper Thin Cutting Disc

Abrasive Sleeve

Calcined Aluminium Oxide Flap Disc

Wechat Service